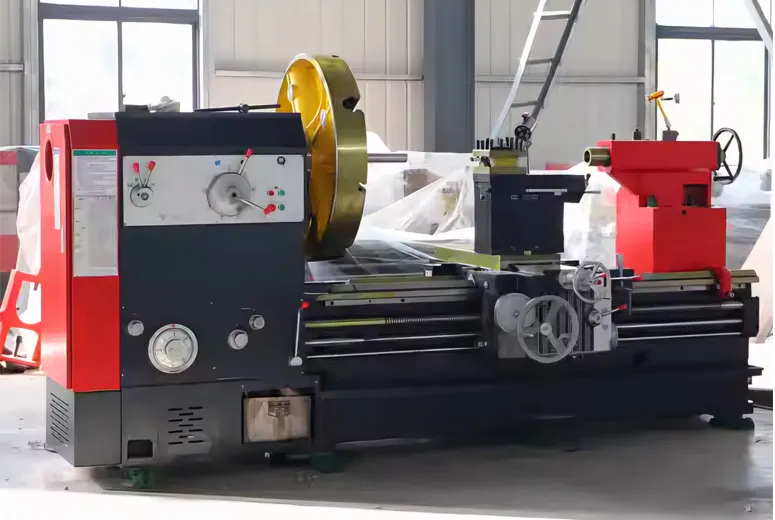

Rangka kasur:

The CFW6163B series lathe has a one-piece bed. The bed body is made of modular integral casting, with good rigidity. The material is high-quality high-grade cast iron, and the castings have undergone aging treatment, resulting in high rigidity and stability. The guide rail adopts medium frequency quenching technology, with a hardened layer of>3mm and a hardness of ≥ HRC48. The surface of the guide rail is ground by high-precision guide rail grinding, with high precision and long service life.

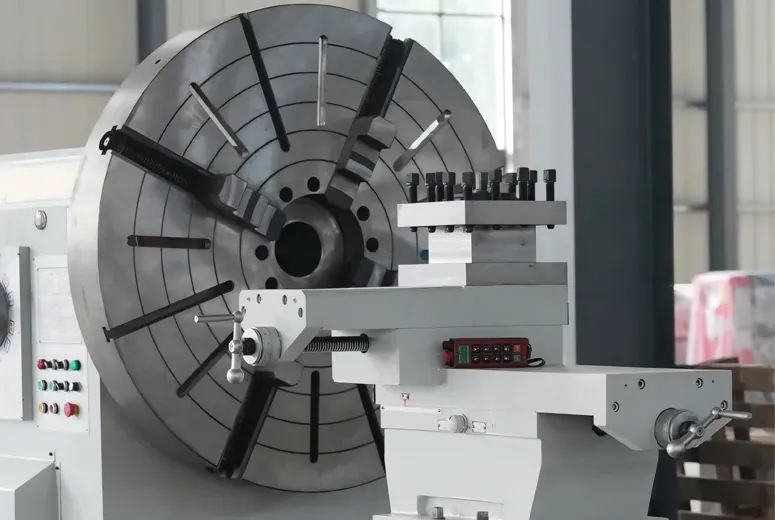

kothak Spindle:

The spindle is made of integral forging material, with strong rigidity and good stability. The main shaft bearing adopts domestically renowned bearings with high precision and stable accuracy retention. The spindle box is a box type multi compartment structure with good rigidity and high support force. The gears inside the spindle box are subjected to high-frequency quenching and grinding technology, resulting in stable transmission, low noise, and resistance to damage. The interior of the headboard box adopts forced lubrication for better lubrication effect. The overall noise of the machine is tested according to GB/T6769-1997 "Measurement Method for Sound Pressure Level of Metal Cutting Lathe Noise", and the sound pressure level of the machine tool's idle running noise is ≤ 83dB. The spindle box adopts a forced hydraulic oil lubrication form, and the headstock gears and bearings are lubricated by a dedicated oil pump. The front end of the spindle adopts a double sealed structure of labyrinth and tooth groove, which can effectively prevent oil leakage and foreign objects from entering the spindle box.

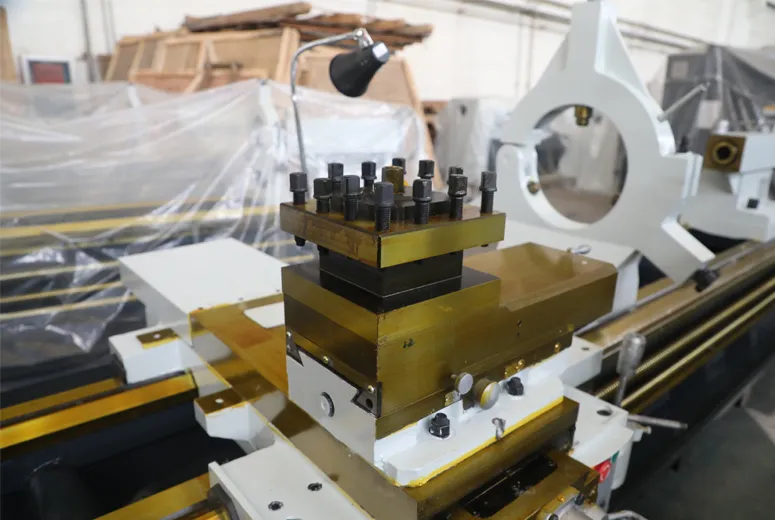

Sadel kasur:

The saddle dovetail guide rail adopts medium frequency quenching technology, with a hardened layer of>3mm and a hardness of ≥ HRC42, making the guide rail wear-resistant and easy to move.

Piranti mesin iki bisa nindakake macem-macem tugas ngowahi, kayata ngowahi permukaan silinder njero lan njaba, permukaan conical, lan permukaan puteran liyane, ngowahi pasuryan mburi, lan macem-macem benang sing umum digunakake. Bisa ngolah bahan kayata baja, wesi tuang, lan logam non-ferrous. Akurasi dimensi saka bagean sing diproses ing alat mesin iki bisa tekan tingkat IT7, lan kekasaran permukaan sing luwih cilik bisa dipikolehi.

1. Alat mesin iki bisa nindakake mesin kasar lan tliti bagean mekanik, utamané cocok kanggo industri kayata otomotif, militer, lan mesin, kanggo irit, massively, lan kanthi akurat ngolah bagean puteran.

2. Alat mesin iki bisa ngolah bahan kayata baja, wesi tuang, lan logam non-ferrous.

3. Alat mesin iki uga cocok kanggo ngowahi permukaan silinder njero lan njaba, permukaan conical, benang, bolongan pengeboran, bolongan engsel, lan awak puteran sing mlengkung saka poros cilik lan medium-ukuran lan bagean disk. akurasi Processing sawijining bisa tekan tingkat IT7, lan roughness lumahing workpiece diproses bisa tekan Ra1.6.

Kisaran mesin alat mesin kudu ditemtokake miturut spesifikasi lan paramèter teknis alat mesin. Pangolahan ngluwihi spesifikasi lan paramèter sing diidini saka alat mesin dilarang. Yen ora, bisa ngrusak alat mesin lan malah nyebabake kacilakan ciloko pribadi. Deleng paramèter teknis alat mesin kanggo sawetara mesin.

Presisi alat mesin iki tundhuk karo standar "Precision of Horizontal Lathes" GB / T4020.

4.1 Maximum turning diameter of machine tool: φ630mm

4.1.1 Rel panuntun alat mesin jembaré: 550

4.2 Dawane benda kerja maksimal: 8000

4.2.1 dawa nglereni maksimum: 7850

4.3 Maximum rotating workpiece diameter on skateboard: φ350mm

4.4 Spindle inner hole diameter: φ104mm

4.5 Taper ngarep bolongan kumparan: 1: 20/120

4,6 kacepetan seri: 18 jinis 7,5 ~ 1000r / min

4.7 Tarif feed vertikal lan horisontal: 64 jinis.

4.8 Tip spindle: Morse 5

4.9 Kacepetan gerakan cepet saka pelana: 4000mm / min

4.10 Motor utama: Y160M-4-B3 11KW 1460r/min

4.11 Cepet obah motor: 1.1KW 1450r/min

4.12 Gear pump: CB-B6 mbalikke 6ml/r 2.5Mpa 1450r/min

4.13 Diameter lengan kursi ekor: 100mm

4.14 Stroke lengan kursi ekor: 250mm

4.15 Taper lengan kursi ekor: Morse 5

4.16 Ukuran: 10160X1455X1400 (dawa X jembaré X dhuwur)

4.17 Machine weight: ≈ 8000Kg

| nomer seri | jeneng | Produsen utawa supplier | jumlah | Cathetan |

| 1 | CFW6163B mesin bubut horisontal | Dandong Huajun | 1 unit | Dipasang |

| 2 | Telung rahang Chuck K11315C / C11 | Merek domestik sing kondhang | 1 atur | Dipasang |

| 3 | Bagian asli listrik utama | Delixi | 1 atur | Dipasang |

| 4 | Following tool holder (φ30-φ130) | Dandong Huajun | 1 unit | Dipasang |

Cathetan: Dhaptar komponen kunci ing ndhuwur lan merek komponen utama / komponen sing kadhaptar ing persetujuan teknis iki mung nuduhake negara lan wilayah sing merek kasebut, lan ora ngrujuk marang asal-usul komponen utawa komponen kasebut.

| nomer seri | jeneng | Spesifikasi | jumlah | Cathetan |

| 1 | set ndhuwur | Metrik 120/Mohs No. 5 | 1 | |

| 2 | kedudukan ndhuwur | 5 S25-2 | 1 | |

| 3 | Kunci wadhah alat | S92-5 | 1 | |

| 4 | Ngawut-awut lemah lan kacang | GB799-1988 M24X400 | Miturut dawa mesin | |

| 5 | tank banyu cooling | 1 atur | ||

| 6 | Pandhuan kanggo nggunakake | 1 porsi | Inggris netral | |

| 7 | Sertifikat | 1 porsi | Inggris netral | |

| 8 | Daftar kemasan | 1 porsi | Inggris netral |

Standar manufaktur utama sing diadopsi dening alat mesin iki

(1) Kahanan Teknis Umum kanggo Alat Mesin Pemotongan Logam GB9061-2006

(2) Ketentuan Teknis Umum kanggo Perlindhungan Keamanan Alat Mesin Pemotongan Logam GB15760-1995

(3) Ketentuan Teknis Umum Perakitan Alat Mesin Pemotongan Logam JB/T9874-1999

(4) Cara uji kinerja bubut horisontal JB/T2322.1-2002

(5) Peralatan listrik mesin industri Bagean 1 Spesifikasi teknis umum GB/T5226.1-1995

✦Urip piranti mesin yaiku 12 wulan. Sajrone periode iki, sembarang malfunctions disebabake desain, manufaktur, utawa kualitas suku cadang bakal ditangani utawa diganti dening Party A gratis.

✦Sawise periode garansi, Pihak A bakal nyedhiyakake pangopènan lan layanan sing dibayar seumur hidup.

✦ Penyediaan suku cadang lan komponen jangka panjang kanthi rega diskon.

✦Yen ana kerusakan utawa masalah liyane karo alat mesin nalika digunakake, pangguna kudu mungkasi mesin kasebut lan kerja sama karo perusahaan kita kanggo ndandani sadurunge terus nggunakake. Yen ora, karusakan liyane ing piranti mesin sing disebabake iki bakal dadi tanggung jawab pangguna.