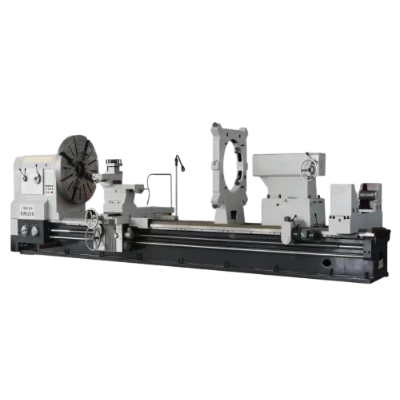

The CNC lathe is an advanced machine tool that combines precision, efficiency, and versatility, offering superior performance in various industries, from aerospace to automotive manufacturing. With its computer numerical control system, the CNC lathe enables automated, highly accurate machining of complex parts with minimal human intervention. This technology allows for consistent and repeatable results, which significantly reduces production errors and downtime. Equipped with high-speed spindles and powerful motors, CNC lathes can handle a wide range of materials, including metals, plastics, and composites, making them ideal for both small batch and mass production. The flexibility of the CNC lathe extends to its ability to perform a variety of operations, such as turning, drilling, boring, and threading, all on a single machine.

The integration of advanced control software allows for real-time adjustments to machining parameters, optimizing cutting conditions and improving overall productivity. The machine’s robust design ensures stability during high-speed operations, while its user-friendly interface makes programming and setup quick and intuitive. Additionally, modern CNC lathes are equipped with automated tool changers, enabling continuous production without operator intervention, further enhancing efficiency. The precision and reliability of CNC lathes make them indispensable in industries where tight tolerances and high-quality finishes are required. With the ability to process complex geometries and intricate designs, they are essential for manufacturing parts with high dimensional accuracy and superior surface finishes. As industries demand more from their manufacturing processes, CNC lathes continue to evolve, incorporating innovations such as AI-powered automation and IoT connectivity, providing manufacturers with cutting-edge solutions to meet the growing needs of modern production.