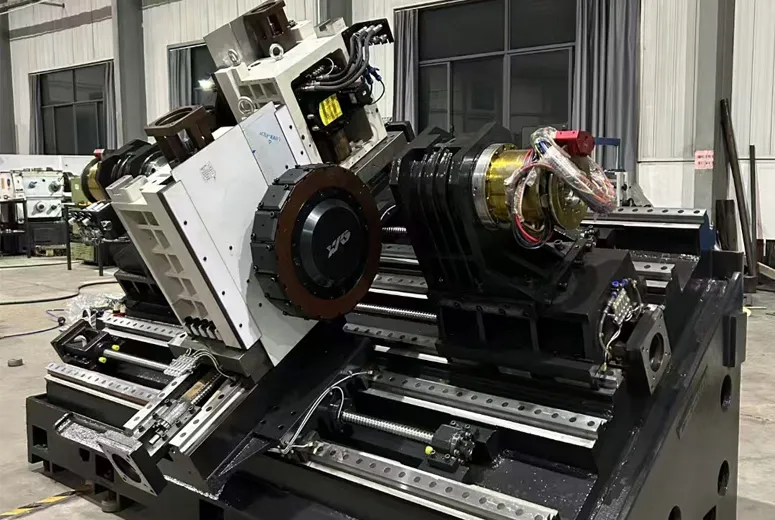

The structural form and technical characteristics of key and important components

1. The transmission adopts imported linear rolling guides from Taiwan to meet the requirements of high speed and efficiency, reduce frictional resistance and temperature rise deformation, improve machining accuracy, and ensure long-term stability of cutting accuracy.

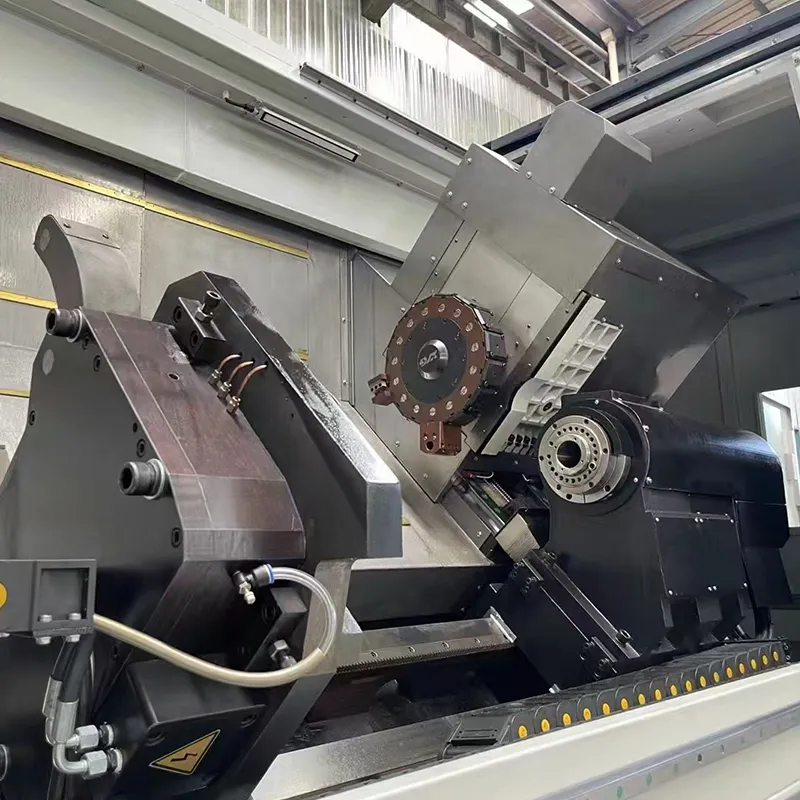

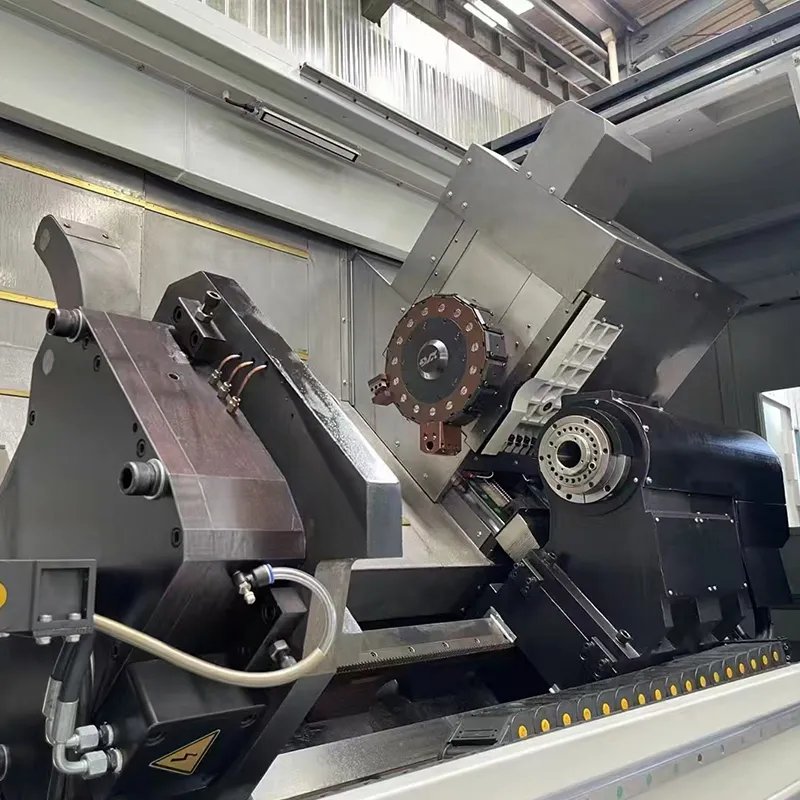

2. The inclined bed CNC lathe adopts domestically produced or imported high rigidity horizontal hydraulic servo turret tool holder, with high positioning accuracy, fast tool changing speed nearby, and small re cutting deformation.

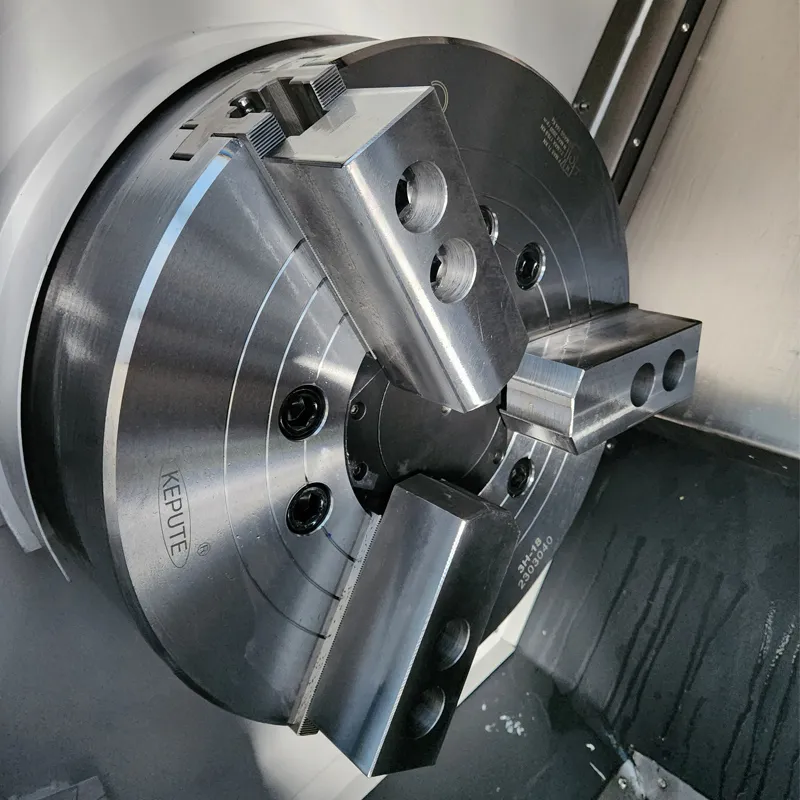

3. Standard configuration: spindle stepless speed regulation, hydraulic chuck, hydraulic tailstock, horizontal eight station tool holder, enclosed protection.

4. The inclined bed CNC lathe adopts a 45 degree overall inclined bed structure, which can maintain the stability of machine accuracy during heavy cutting.

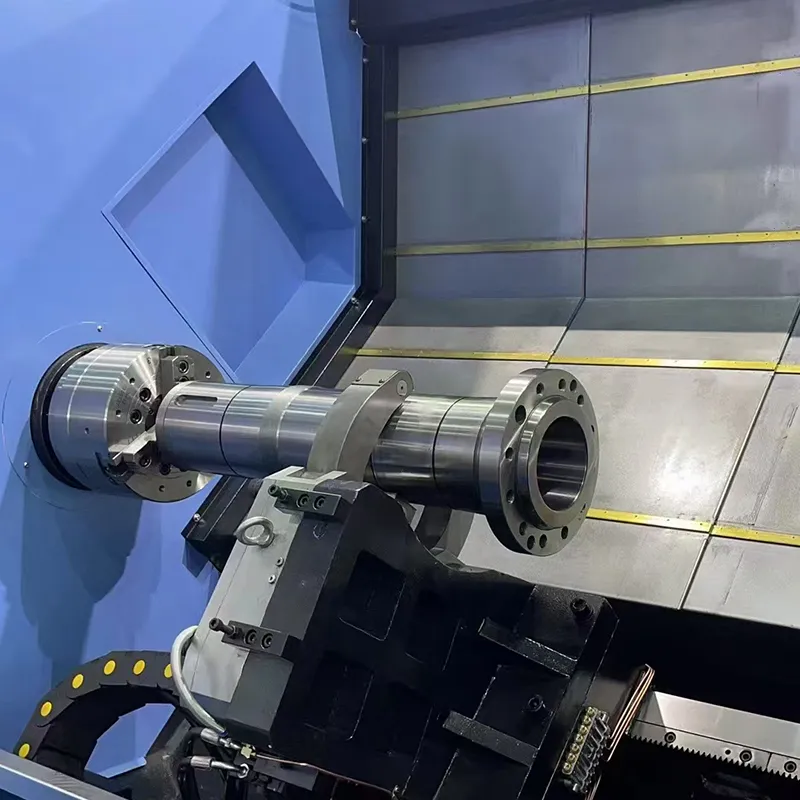

5. The X and Z axis servo motors are directly connected to precision ball screws through elastic couplings, with high precision. The two ends of the screw are fixed, which improves the support stiffness of the support seat and minimizes the twisting and deformation of the screw caused by frequent high-speed positioning and re cutting. The bearings are made of high-quality domestic screw special 60 degree angular contact paired precision bearings, which are high-speed and high-precision.

6. High precision, high rigidity, built-in hydraulic tailstock, automatic hydraulic locking.

7. When designing the bed CNC lathe, the spindle box bearing adopts double row cylindrical roller bearings with high rigidity, and corresponding measures are taken to reduce the thermal deformation of the spindle for heat dissipation, so as to maintain the relative stability of the spindle axis during long-term operation.

8. The inclined bed CNC lathe adopts full guide rail protection, and the cooling box and chip conveyor are separated from the main engine to ensure the accuracy of the machine tool is not affected by thermal cutting.

9. The electrical unit cabinet of the machine tool has good sealing and is equipped with an electrical cabinet cold air switch, ensuring the normal operation of the CNC system in high temperature and high humidity environments of the machine tool.

10. The machine tool pays attention to the design of edge technology, ensuring reliable protection. When subjected to strong cutting and high-pressure spraying of coolant, there are no iron filings or coolant splashing and leaking outside the machine tool.

11. Hydraulic chuck clamping, loosening, and tailstock sleeve extension can be controlled by foot pedal in addition to program control, which is convenient and fast.

12. Hydraulic pressure adjustment adopts panel type rotary operation, with dial display, ensuring safe and convenient adjustment.

| project | unit | parameter |

| Maximum rotation diameter of the bed | mm | Ф520 |

| Maximum rotation diameter on the skateboard | mm | Ф350 |

| Maximum processing length | mm | 1000 |

| Spindle head type | GB59001 | A2-8 |

| Spindle through hole diameter | mm | Ф82 |

| Spindle speed | r/min | 50-2200 |

| Main motor power (servo) | kw | 15 |

| Collet size/Chuck size | lnch | Hydraulic chuck 10" |

| Tailstock sleeve diameter/stroke | mm | Ф100/120 |

| Tailstock sleeve hole taper | Mohs No. 5 | |

| X-direction travel | mm | 300 |

| Z-direction travel | mm | 1000 |

| X/Z fast forward speed | m/min | 15/15 |

| Tool holder form | Tailian 12-station hydraulic servo tool holder | |

| Tool size | mm | 25*25 |

| Main drive V-belt type specifications | mm | V shape |

| Overall dimensions (length*width*height) | mm | 3600*1800*2200 |

| weight | kg | 5400 (including pin arranging machine) |

| serial number | Name | model | Manufacturer or supplier | quantity | Remark |

| 1 | CNC system | Guangshu 980TC3 system | Guangshu | 1 set | |

| 2 | Main motor | 15KW | alpha | ||

| 3 | X-axis motor (with brake) | 130ST11N | Guangshu | ||

| 4 | Z-axis motor | 130ST11N | Guangshu | ||

| 5 | Spindle bearings | NN3024K P4 | Tianjiu | 1 group | |

| 6 | 7020 B DB P4 | Tianjiu | |||

| 7 | NN3022K P4 | Tianjiu | |||

| 8 | Spindle grease | Import (Germany) | |||

| 9 | Linear guide | Z 45 X 35 | Taiwan Silver (Roller) | 1 set | |

| 10 | ball screw | Z 4012 X4012 | Taiwan brand | 1 set | |

| 11 | Lubrication unit | Guangzhou Dingrun | 1 set | ||

| 12 | Hydraulic chuck | 10 inches (Zhongshi) | Changzhou Bedford | ||

| 13 | Hydraulic unit | Jiahua CNC | 1 set | ||

| 14 | pin arranging machine | Chain plate type | Cangzhou Yinhao | 1 set | |

| 15 | Powered tool holder | SLT-80-12T servo eight stations | Taiwan Brand (Online) | 1 piece | |

| 16 | cooling pump | 0.55KW | beijing sweer | 1 piece |

The precision of machine tools shall comply with the GB/T16462-2007 standard for precision testing of CNC horizontal lathes

| Inspection items | factory standard | |

| Processing accuracy | IT6 | |

| Processing workpiece roundness | 0.005mm/Ф75 | |

| Machining workpiece cylindricity | 0.010mm / 150mm | |

| Machining workpiece flatness | 0.010mm/Ф200mm | |

| Surface roughness of machined workpiece | Ra1.25μm | |

| Positioning accuracy | X-axis | 0.01mm |

| Z axis | 0.012mm | |

| Duplicate targeting | X-axis | 0.004mm |

| Accuracy | Z axis | 0.004mm |

| serial number | Attachment name | Model specifications | quantity | Remark |

| 1 | Footing iron | 1 set | Our factory | |

| 2 | Turning tool holder | External knife pressing block 25X25 | 5 sets | Our factory |

| End tool holder 25X25 | 1 | Our factory | ||

| Boring tool holder φ40 | 3 | Our factory | ||

| Knife holder f32, f25, f20 | 1 each | Our factory | ||

| 3 | Chip cooling box | 1 set | Domestic | |

| 4 | Hydraulic tail stage | 1 set | Our factory |

1. Machine Tool Operation Manual 2, CNC System Operation Manual

3. CNC System Maintenance Manual 4, Hydraulic Schematic Diagram

5. Electrical schematic diagram, wiring diagram, ladder diagram, parameter setting table

6. Machine Tool Accuracy Inspection Certificate

7. Hydraulic chuck manual 8, turret tool holder manual

1. GB/T16462_1996 Precision Inspection of CNC Horizontal Lathes;

2. JB/T4368.3_96 Technical Conditions for CNC Horizontal Lathes;

3. GB9061_88 General Technical Conditions for Metal Cutting Machine Tools;

4. ZBnJ50008.1-88 General Technical Conditions for Mechanical Processing of Metal Cutting Machine Tools