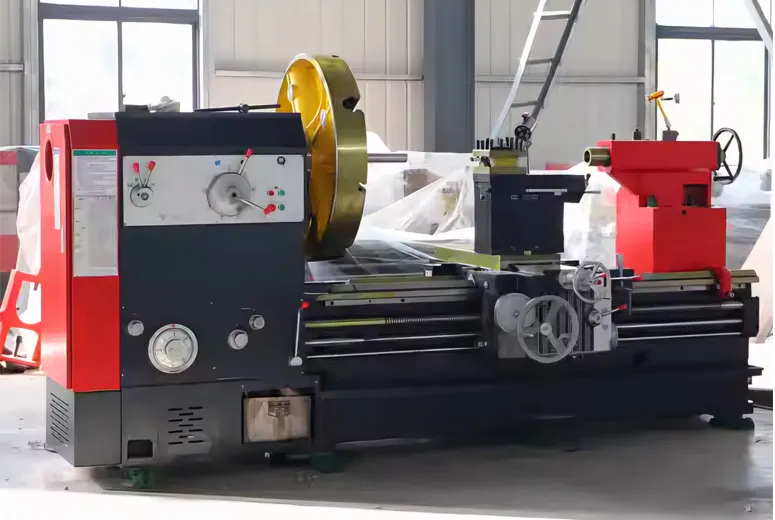

Bed frame:

The CFW6163B series lathe has a one-piece bed. The bed body is made of modular integral casting, with good rigidity. The material is high-quality high-grade cast iron, and the castings have undergone aging treatment, resulting in high rigidity and stability. The guide rail adopts medium frequency quenching technology, with a hardened layer of>3mm and a hardness of ≥ HRC48. The surface of the guide rail is ground by high-precision guide rail grinding, with high precision and long service life.

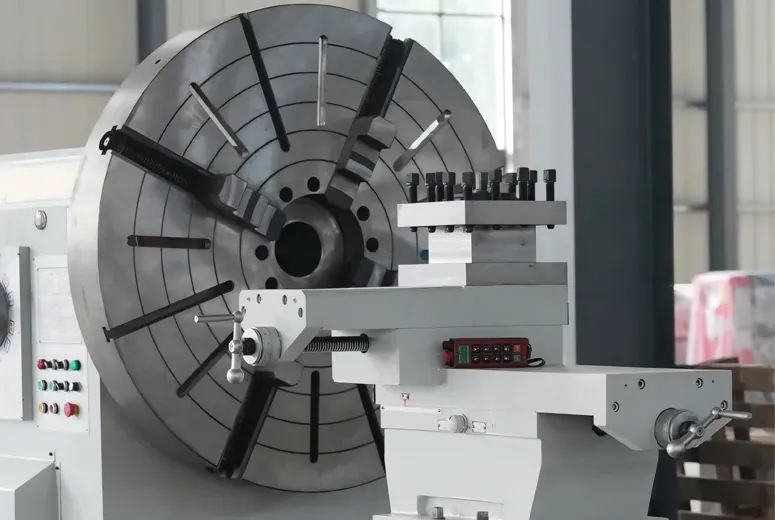

Spindle box:

The spindle is made of integral forging material, with strong rigidity and good stability. The main shaft bearing adopts domestically renowned bearings with high precision and stable accuracy retention. The spindle box is a box type multi compartment structure with good rigidity and high support force. The gears inside the spindle box are subjected to high-frequency quenching and grinding technology, resulting in stable transmission, low noise, and resistance to damage. The interior of the headboard box adopts forced lubrication for better lubrication effect. The overall noise of the machine is tested according to GB/T6769-1997 "Measurement Method for Sound Pressure Level of Metal Cutting Lathe Noise", and the sound pressure level of the machine tool's idle running noise is ≤ 83dB. The spindle box adopts a forced hydraulic oil lubrication form, and the headstock gears and bearings are lubricated by a dedicated oil pump. The front end of the spindle adopts a double sealed structure of labyrinth and tooth groove, which can effectively prevent oil leakage and foreign objects from entering the spindle box.

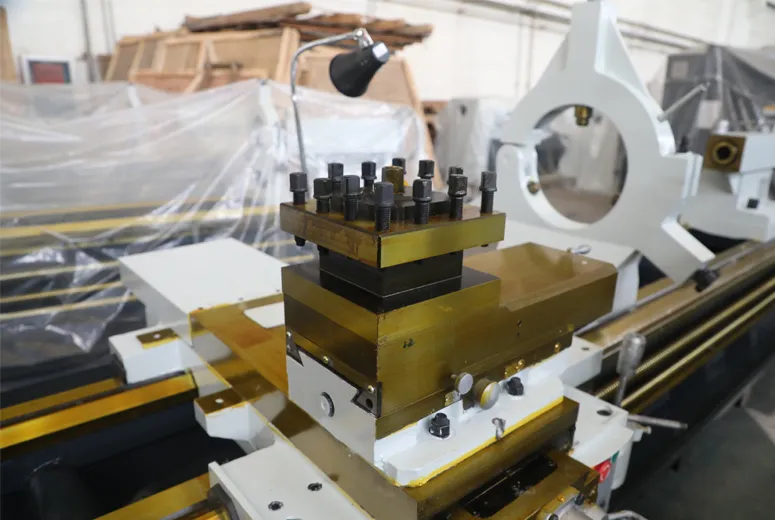

Bed saddle:

The saddle dovetail guide rail adopts medium frequency quenching technology, with a hardened layer of>3mm and a hardness of ≥ HRC42, making the guide rail wear-resistant and easy to move.

This machine tool can undertake various turning tasks, such as turning inner and outer cylindrical surfaces, conical surfaces, and other rotating surfaces, turning end faces, and various commonly used threads. Can process materials such as steel, cast iron, and non-ferrous metals. The dimensional accuracy of the parts processed on this machine tool can reach IT7 level, and a smaller surface roughness can be obtained.

1. This machine tool can perform rough and precision machining of mechanical parts, especially suitable for industries such as automotive, military, and machinery, to efficiently, massively, and accurately process rotating parts.

2. This machine tool can process materials such as steel, cast iron, and non-ferrous metals.

3. This machine tool is also suitable for turning the inner and outer cylindrical surfaces, conical surfaces, threads, drilling holes, hinge holes, and curved rotating bodies of small and medium-sized shaft and disc parts. Its processing accuracy can reach IT7 level, and the surface roughness of the processed workpiece can reach Ra1.6.

The machining range of the machine tool should be determined according to the specifications and technical parameters of the machine tool. Processing beyond the specifications and allowed parameters of the machine tool is prohibited. Otherwise, it may damage the machine tool and even cause personal injury accidents. Refer to the technical parameters of the machine tool for the machining range.

The precision of this machine tool complies with the GB/T4020 "Precision of Horizontal Lathes" standard.

4.1 Maximum turning diameter of machine tool: φ630mm

4.1.1 Machine tool guide rail width: 550

4.2 Maximum workpiece length: 8000

4.2.1 Maximum cutting length: 7850

4.3 Maximum rotating workpiece diameter on skateboard: φ350mm

4.4 Spindle inner hole diameter: φ104mm

4.5 Front taper of spindle hole: 1:20/120

4.6 Speed series: 18 types 7.5~1000r/min

4.7 Vertical and horizontal feed rates: 64 types.

4.8 Spindle tip: Morse 5

4.9 Quick movement speed of saddle: 4000mm/min

4.10 Main motor: Y160M-4-B3 11KW 1460r/min

4.11 Fast moving motor: 1.1KW 1450r/min

4.12 Gear pump: CB-B6 reverse 6ml/r 2.5Mpa 1450r/min

4.13 Tail seat sleeve diameter: 100mm

4.14 Tail seat sleeve stroke: 250mm

4.15 Tail seat sleeve taper: Morse 5

4.16 Dimensions: 10160X1455X1400 (length X width X height)

4.17 Machine weight: ≈ 8000Kg

| serial number | name | Manufacturer or supplier | quantity | Remark |

| 1 | CFW6163B horizontal lathe | Dandong Huajun | 1 unit | Installed |

| 2 | Three-jaw chuck K11315C/C11 | Well-known domestic brands | 1 set | Installed |

| 3 | Main electrical original parts | Delixi | 1 set | Installed |

| 4 | Following tool holder (φ30-φ130) | Dandong Huajun | 1 unit | Installed |

Note: The above list of key components and the brands of key components/components listed in this technical agreement only indicate the country and region to which the brand belongs, and do not refer to the origin of the component or component.

| serial number | name | Specification | quantity | Remark |

| 1 | top set | Metric 120/Mohs No. 5 | 1 | |

| 2 | top notch | 5 S25-2 | 1 | |

| 3 | Tool holder wrench | S92-5 | 1 | |

| 4 | Ground screws and nuts | GB799-1988 M24X400 | According to machine length | |

| 5 | cooling water tank | 1 set | ||

| 6 | Instructions for use | 1 serving | English neutral | |

| 7 | Certificate | 1 serving | English neutral | |

| 8 | Packing list | 1 serving | English neutral |

The main manufacturing standards adopted by this machine tool

(1) General Technical Conditions for Metal Cutting Machine Tools GB9061-2006

(2) General Technical Conditions for Safety Protection of Metal Cutting Machine Tools GB15760-1995

(3) General Technical Conditions for Assembly of Metal Cutting Machine Tools JB/T9874-1999

(4) Horizontal lathe performance test method JB/T2322.1-2002

(5) Industrial machinery electrical equipment Part 1 General technical specifications GB/T5226.1-1995

✦The shelf life of the machine tool is 12 months. During this period, any malfunctions caused by design, manufacturing, or quality of spare parts shall be handled or replaced by Party A free of charge.

✦After the warranty period, Party A shall provide lifelong paid maintenance and services.

✦Long term provision of spare parts and components at discounted prices.

✦If there is a malfunction or other problem with the machine tool during use, the user must stop the machine and cooperate with our company for repair before continuing to use it. Otherwise, any further damage to the machine tool caused by this will be the responsibility of the user.